Oxyacetylene Flame Cutting Works Best on Which of the Following

The following five steps for lighting and adjusting the flame on an oxyacetylene cutting torch are not in the correct order. Pure oxygen was used instead of ordinary air to increase the flame temperature.

Principle Of Oxy Acetylene Cutting Process

Cutting Air Carbon Arc Cutting Oxyacetylene Cutting Process Name.

. When the flame is adjusted as described above hold the torch with the left hand grasping it well toward the head and the right hand on the handle with the fingers controlling the lever valve. To obtain this type of flame the torch should first be adjusted to a neutral flame. Oxygen-acetylene gas welding was first developed and used in 1903 by the French Engineers Edmond Fouche and Charles Picard.

9202007 12 Common Vocabulary. This combination process produces aflame with heat exceeding 3000C which is enough to cut through mild steel. Metal Waste Dross.

Mild steel is any steel that has a carbon component that is a maximum of 03. The oxy-acetylene cutting torch primarily works via a combustion process that is caused by the mixture of acetylene and oxygen. Should rest on the material being cut whenever possible to steady the torch.

The oxygen to acetylene ratio is 11-121 for neutral flames. Oxy-acetylene Cutting. It consists of a very short pointed white inner cone and a shorter outer envelope.

Which of the following is the flammable gas used in the oxyacetylene welding process. Oxyacetylene welding commonly referred to as gas welding is a process which relies on combustion of oxygen and acetylene. Neutral flame 50 oxygen and 50 acetylene Carburizing flame or reducing flame less oxygen Oxidizing flame excess oxygen These flames are divided into three categories on the basis of proportion of oxygen and acetylene in the mixture.

Which of the following is the flammable gas used in the oxyacetylene welding process. Indicate the correct order by placing the number 1 first step through 5 last step in the appropriate blanks. The elbow or forearm.

Work at those and youll have less GRINDING. TF All regulators can be used interchangeably on different types of gas or for different pressure ranges. While joining the molten metal flows together to form a continuous joint.

Forehand welding The filler rod precedes the torch in the direction of the weld Oxidation The combining of oxygen with any other substance Backhand welding The torch tip precedes the filler rod in the direction of the weld Brazing. Acetone is a liquid chemical that stabilizes acetylene and allows the cylinder to be pressurized to _____ psi. OSHA 1910253c5vi Inspect cylinder for dents scratches or damage Open valve on cylinder only ¼ turn in case of fire Cutting Tips for Agriculture Repair Every torch has a tip.

The metal oxidizing process is used to separate the metal at the joint when the flame temperature rises above 1500 degrees Celsius 2732 degrees Fahrenheit. The oxidizing flame has a sharp hissing sound and is easy to recognize. True Use soapy water from a soap that does not contain oil to find gas leaks.

Oxy-fuel welding more commonly known as oxyacetylene welding or gas welding is used for gas welding and gas cutting. Such a flame makes a loud roaring sound. It is most often used for welding of low carbon structural steels and aluminium.

This oxy acetylene ratio compares favorably with the ratio of oxygen to propane which is around 431. TF There are no internal or external moving parts on a regulator or a gauge that requires oiling. 4- open oxygen torch.

How is this possible. Oxy-acetylene process is most suited for the joining of metal sheets or for joining metal plates which are having a thickness of 2mm to 50mm. True The neutral flame is the flame of choice for oxyacetylene cutting.

The chemical action of the oxyacetylene flame. A Always held at 90 to the material b Inclined more for thin material c Inclined more for thick material d Held at a 45 angle to start the cut and straightened to 90 as the cut progresses. Oxyacetylene cutting The rapid oxidation or burning of metal at high temperatures.

Students progress at their own pace and you see a leaderboard and live results. TF The combination welding and cutting torch offers more flexibility because a cutting head. Oxygen and acetylene cylinders are available in a size containing _____ cu ft of gas.

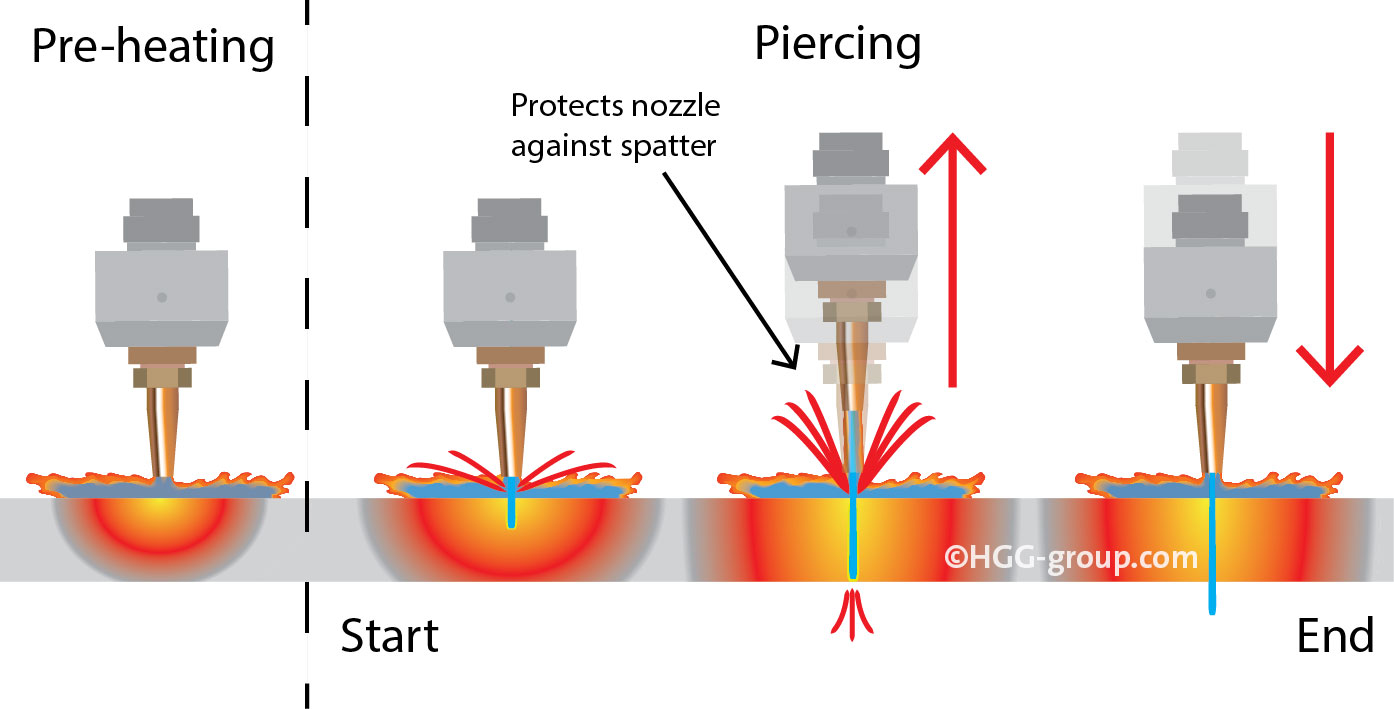

True In an oxidizing flame the inner core will be shorter and the flame will be noisier than the neutral flame. The image mentioned above shows the. The oxidising flame has an excess of oxygen over the acetylene.

3- continue opening acetylene. True Never weld or cut on concrete because overheated concrete may crack and explode. ZMost efficient cutting flame setting zFlame temperature is 5800 Fahrenheit.

The most suitable flame to use when heating with oxyacetylene equipment is. At this temperature level the metal flows freely. When handling oxygen and acetylene cylinders the maximum safe operating pressure for acetylene is _____ psi.

There are basically 3 types of oxy acetylene gas welding flames. This flame is best used for applications such as soft solder brazing annealing and tempering. The process of oxy-acetylene welding is referred to as flame cutting because it is a mixture of flame heating and metal oxidizing.

An oxidizing flame is created when there is more oxygen present than acetylene in the flame. When used for cutting an oxyacetylene torch is. When mixed together in correct proportions within a hand-held torch or blowpipe a relatively hot flame is produced with a temperature of about 3200 degC.

For propylene gas this oxygenfuel ratio is around 371. Control the pace so everyone advances through each question together. A an acetylene flame b a carbonizing flame c an oxidizing flame d a neutral flame.

Cutting tips have pre-heat holes and a cutting jet orifice Tips should be cleaned prior to use Flat file for facing the tip Tip drills or tip cleaners for. The reduction in length of the inner cone is a measure of excess oxygen.

Flame Cutting Openlearn Open University

Oxy Fuel Welding And Cutting Wikiwand

Comments

Post a Comment